- Subject:

- Manufacturing

- Material Type:

- Module

- Provider:

- Ohio Open Ed Collaborative

- Tags:

- Language:

- English

- Media Formats:

- eBook

Chapter 1 - Communication Skills

Chapter 2 - Interpersonal Communication

Chapter 3 - Group Communication

Chapter 4 - Methods of Communication

Business Insights and Careers

Material Requirements Planning-MRP

Material Requirements Planning- MRP

Material Management ERP (video) MRP (Excel)

New Product Development (video)

Once manufacturing companies determine the number of assembled products that they need to produce, they use a methodology called Material Requirements Planning to calculate the number of components, parts and subassemblies that make up this one assembled product, and whether they make them internally or buy them from their suppliers. This planning method is very commonly used for assembled products that are produced in repetitive processes.

In order to plan how much and when to produce/buy parts or components that make up the assembled product, we need to have the following three databases:

Master Schedule

Bill of materials

Inventory records

Master Schedule

The master schedule provides all the information necessary about the finished products (also called an end item). Information regarding demand, due dates, and quantity on hand (inventory levels) are stored in this database. The MRP relies on this information to generate a detailed materials requirement plan. Thus, it is important that Master Schedule database is accurate and is updated regularly to reflect the changes in customer demand.

Bill of Materials (BOM)

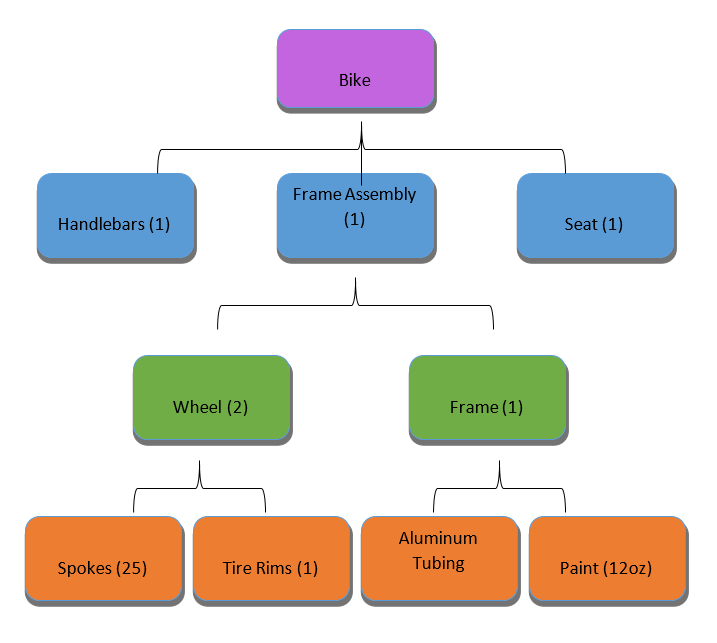

Every assembled product has its own Bill of Materials. A BOM is a list of all the components, parts, sub-assemblies and the quantities of each needed to produce one finished assembled product. A product structure tree is a visual representation of a BOM where the parts, components and subassemblies are hierarchical. That is, the assembled product is at the top of the tree and every level in the tree is a further detailed breakdown of the parts or subassemblies. The following is a product tree showing the requirements of BOM of a bicycle:

The above BOM for a bicycle shows the requirements to assemble one bicycle. One bicycle requires the subassembly of one handlebar, one frame assembly, and one seat. One frame assembly, in return, is made up of assembling two wheels and one frame. Each wheel contains 25 spokes and one tire rim. And each frame consists of an aluminum Tubing and 12 ounces of paint.

Inventory Records Before manufacturing companies start producing the assembled products, they need to check the quantity of parts and components on hand, the quantities already ordered from the suppliers, and lead time to receive the orders from the suppliers. For example, if there is on hand inventory of seats for the bicycle assembly, then the company will use them first before ordering (or making) more to meet the demand. Thus, the production manager needs to know the inventory levels of each parts and components before placing orders from suppliers.

Example: Lets assume that the bicycle manufacturer received an order for 100 bicycles for next month. They have currently 75 tire rims in inventory. Using the BOM, we can calculate that for one bicycle we need two wheels and each wheel needs one rim, thus, the requirement for rims for one bicycle is 2, and for 100 bicycle the requirement is 200. Since there are already 75 rims in inventory, the net rim requirement is 125. Thus, the procurement manager needs to place an order from the suppliers to purchase at least 125 rims for the production of 100 bicycles. When end items have hundreds and thousands of parts and components the BOM as well as calculation of the net production requirements become complex and requires computerized systems. It also becomes difficult to plan the capacity needed to make parts or subassemblies and requires managers to evaluate make or buy options carefully. Today, manufacturing companies use ERP (Enterprise Resource Planning) software to connect manufacturing plans with human resources, financials, sales and supply chain management databases in order to make sure the plans are realistic, and manufacturing companies can achieve their production goals within given resources. |

Communications

Supplier Selection and Management

Supplier Management

Supplier Realtionships (video)

Manufacturing companies work with many different suppliers to acquire services and materials that are needed to run their businesses. In recent years, supplier management has become an important topic in operations management because of the challenges of doing business in global markets and the increase in cost of raw materials. In order to better manage their suppliers, manufacturing companies use tier systems. According to this method, not all suppliers are considered equal, and some suppliers might be the critical links in the supply chain. Japanese manufacturing companies introduced a supplier tier system where Tier 1 suppliers are considered the most important and the closest to the manufacturing company. Tier 1 suppliers provide components directly to the manufacturer. They usually have long experience in the industry, they are certified, and technically capable. The Tier 2 suppliers supply to the Tier 1 suppliers and Tier 3 companies supply to the Tier 2 suppliers, and, so on. Tiered supplier relationships are common in auto manufacturing since components and sub-assemblies such as breakes and engine parts are complex and must comply with tight quality standards. Tier 1 companies work closely with manufacturers to improve quality, reduce waste, and cut costs. They also share information with manufacturers as well as other tiered suppliers to improve the overall supply chain performance.

Choosing Suppliers

Manufacturing companies take into consideration many factors when deciding which suppliers to work with. In general, sourcing teams evaluate suppliers based on the factors that relate to supplier capabilities and rank them as the best or the most suitable. The following is a list of factors commonly used:

Quality

Delivery

Price

Reputation

Company size

Financial health

Ethics

Clearly, at the top of the list is the quality of the parts and components suppliers provide to manufacturing companies. If defective parts are shipped to manufacturers without quality control at the supplier’s site, the cost of quality at the manufacturer site increases exponentially. Similarly, the delivery performance of the supplier, and the price of the components all impact the cost of goods sold by the manufacturer. Thus, the manufacturer’s performance mostly depends on its supplier’s performance and that is why supplier selection is considered to be a critical strategic decision.

In addition to the cost-related factors during the supplier evaluation process, manufacturers also consider the business reputation of the suppliers, whether fiscally they are in good position, whether the suppliers grow as the manufacturer’s business grows, and whether the suppliers had any ethics violations.

Vendor Managed Inventory (VMI)

Some of the manufacturing companies allow their suppliers to monitor and replenish parts when they are in low volume at the manufacturer’s inventory site without issuing purchase orders. That is, suppliers have the responsibility for owning, monitoring and replenishing the inventories at the manufacturer’s site. Suppliers send weekly or monthly reports and invoices (mostly through electronic data systems) to manufacturers for payment. This allows the manufacturer to reduce overhead cost and decreases the assets manufacturers own.

For example, at a big job shop such as the Tronair facility in Toledo, Ohio, where a variety of ground support equipment for airlines is produced, different color bins are used to store parts and components that are assigned to different suppliers. This makes it easy for a supplier to find and replenish inventories in the Tronair facility. RFID tags and sensors make it available for suppliers to monitor inventory levels in real time, and allow dispatching of shipments only when they are needed. The delegation of authority to manage the manufacturer’s inventories by suppliers significantly reduces supply chain logistics cost and improves efficiency.

Process Flow Charts and Selection

Flow Process Charts

Process Types (video)

Design for Disassembly and Reuse (video)

Sometimes manufacturing companies select a specific operation to be studied in order to improve the process, reduce cost, or improve productivity. For an operation to be studied in detail, a documentation of the current method is needed. Flow process charts are used for this purpose. Flow process charts exhibit the overall flow (or steps) of the operation using symbols and text. It shows the movement of the operator, as well as movement of the material. Once constructed, this chart can help operation managers identify non-value added steps in the process for elimination.

Process Chart Symbols:

Operation ¢

Transportation è

Storage u

Delay ×

Inspection ☐

Example: Flow Process Chart for Gear Manufacturing.

Based on the information presented about the process, the operations manager can identify areas for improvement. The following questions can help with this process:

How can delays be eliminated?

Can travel distances be shortened?

Can processes be grouped for efficiency?

Can any of the activities be automated to reduce human error, and thus eliminate inspection?

As can be seen from the table below, the process requires nine transportation and five waiting steps in the process. The manufacturing process can be improved by eliminating or reducing the number of times the material is being handled. This can be achieved by reorganizing the location of machines. Machines can be close to each other in a U shape to reduce waiting and transportation. This type of a layout is called cellular manufacturing design and is common in job shops.

Activity | Symbol |

Operation | ¢ |

Transport | è |

Inspection | ☐ |

Delay | × |

Storage | u |

Element Description |

|

| Symbols

|

50mm | ¢ | è | ☐ | × | u |

50mm 1004 bar from stores |

|

|

|

| u |

Sent to cutting machine |

| è |

|

|

|

Cut to size | ¢ |

|

|

|

|

Sent to lathe |

| è |

|

|

|

Delay or wait |

|

|

| × |

|

Facing drilling and reaming | ¢ |

|

|

|

|

To lathe |

| è |

|

|

|

Facing of other side, turn to size | ¢ |

|

|

|

|

To gear hobbing machine

|

| è |

|

|

|

Wait |

|

|

| × |

|

Machine the Gear | ¢ |

|

|

|

|

To inspection |

| è |

|

|

|

Wait |

|

|

| × |

|

Inspection for size |

|

| ☐ |

|

|

To heat treatment dept. |

| è |

|

|

|

Wait |

|

|

| × |

|

Hardening | ¢ |

|

|

|

|

To inspection |

| è |

|

|

|

Wait |

|

|

| × |

|

Inspection for hardness |

|

| ☐ |

|

|

To spare part stores |

| è |

|

|

|

Storage for reissue |

|

|

|

| u |